0102030405

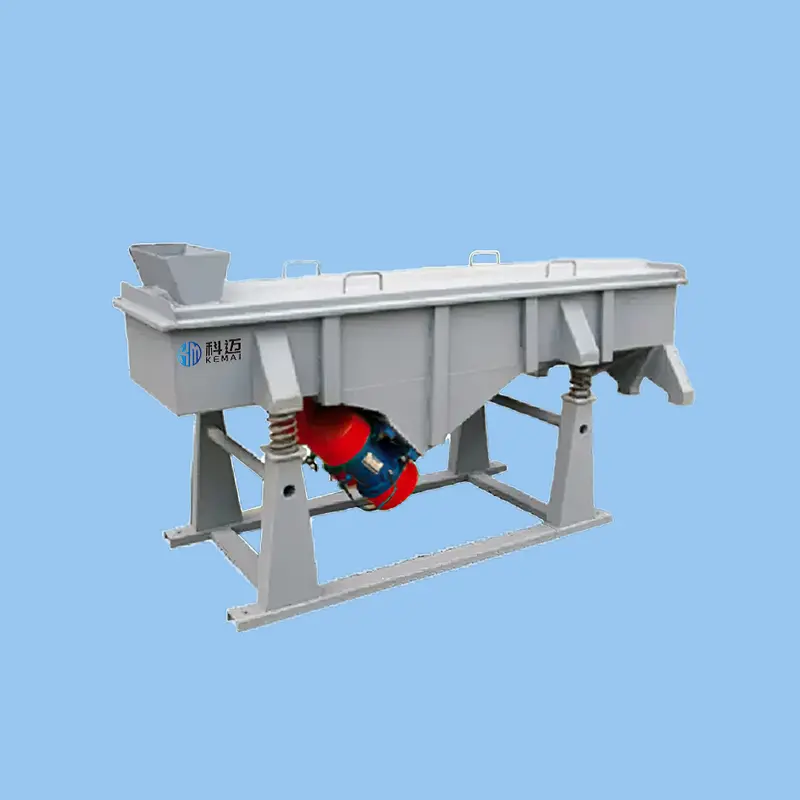

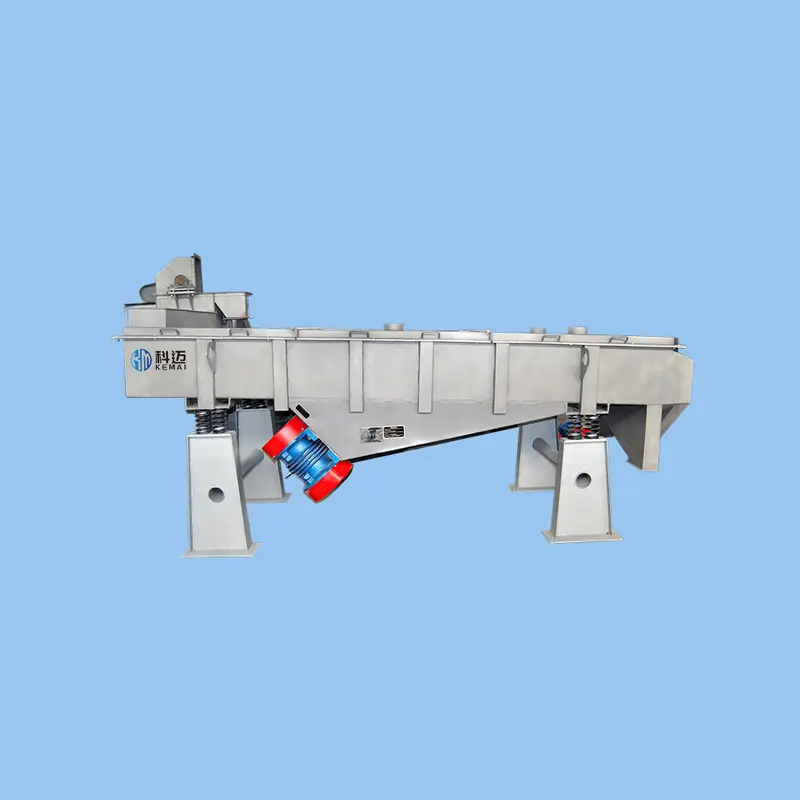

High-performance ZXS Linear Vibrating Screen

Working Principle

ZXS series linear vibrating screen is driven by double vibrating motor. When the two vibration motors do synchronous, anti-fV rotation, the eccentric block generated by the excitation force in the direction of parallel to the motor axis offset each other, in the direction perpendicular to the motor axis stacked as a force, so the motion trajectory of the screen machine is a straight line. The two motor shafts have an inclination Angle relative to the screen surface. Under the combined force of the exciting force and the material's self-gravity, the material is thrown up on the screen surface for a straight line movement, so as to achieve the purpose of screening and grading the material. It is suitable for the screening of various dry powder materials with particle size of 0.074-5mm, water content of less than 70% and no viscosity. The maximum feeding size is not more than 10mm.

Characteristic and feature of ZXS series Linear vibrating screen:

(1)Good sealing, very little dust overflow.

(2) Low energy consumption, low noise, long screen life.

(3) High screening accuracy, large processing capacity, simple structure.

(4) Fully closed structure, automatic discharge, more suitable for assembly line operation.

(5) All parts of the screen body are welded by tying steel plates and profiles (part of the body is bolted) the overall stiffness is good, firm and reliable.

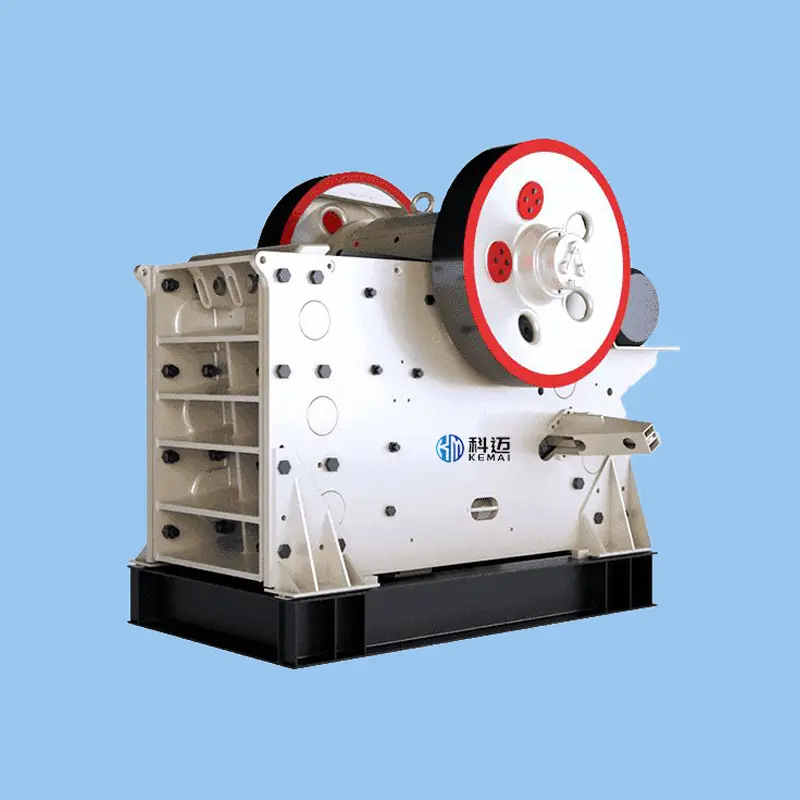

Technical Parameters Of Pe Series Jaw Crusher

| Model | Screen size (mm) | Size of Sieve pore(mm) | Screen slope | amplitude(mm) | layers | Power(Kw) |

| ZXS1020 | 1000×2000 | 0.074-10 | 1-7° | 3-4.5 | 1-6 | 2×(0.4-0.75) |

| ZXS1225 | 1200×2500 | 0.074-10 | 1-7° | 3-4.5 | 1-6 | 2×(1.1-1.5) |

| ZXS1530 | 1500×3000 | 0.074-10 | 1-7° | 3-4.5 | 1-6 | 2×(1.1-2.2) |

| ZXS1540 | 1500×4000 | 0.074-10 | 1-7° | 3-4.5 | 1-6 | 2×(1.5-3.0) |

| ZXS1840 | 1800×4000 | 0.074-10 | 1-7° | 3-4.5 | 1-6 | 2×(2.2-3.7) |

| ZXS2130 | 2100×3000 | 0.074-10 | 1-7° | 3-4.5 | 1-6 | 2×(2.2-3.7) |

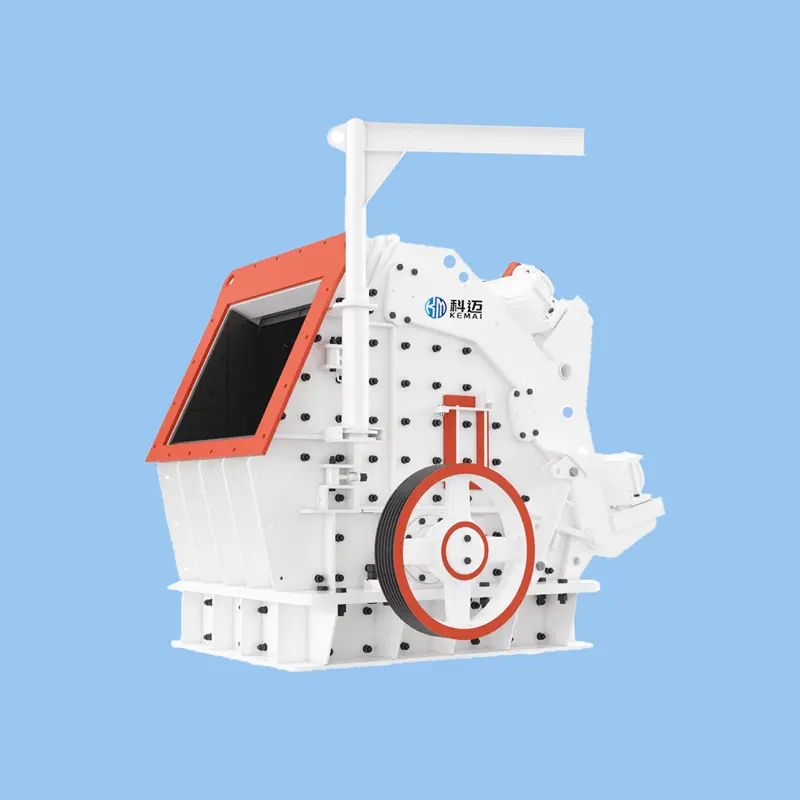

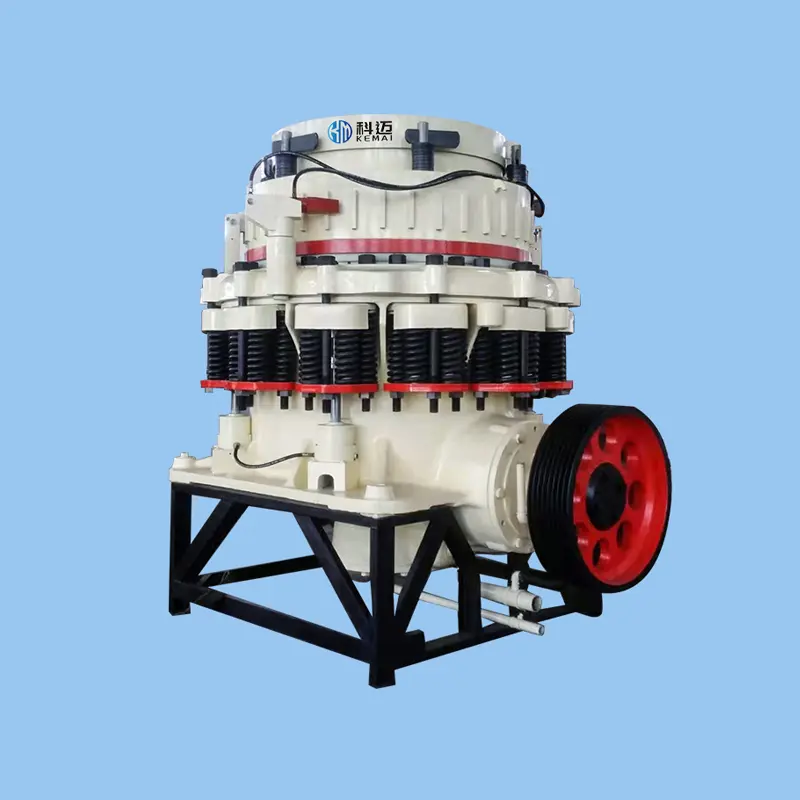

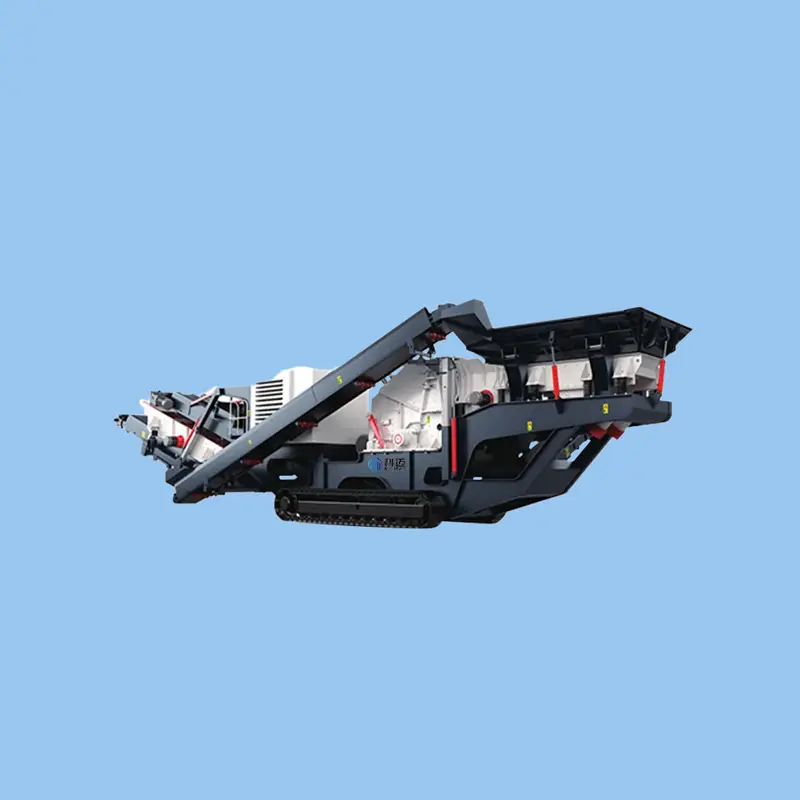

Some Of Our Product