0102030405

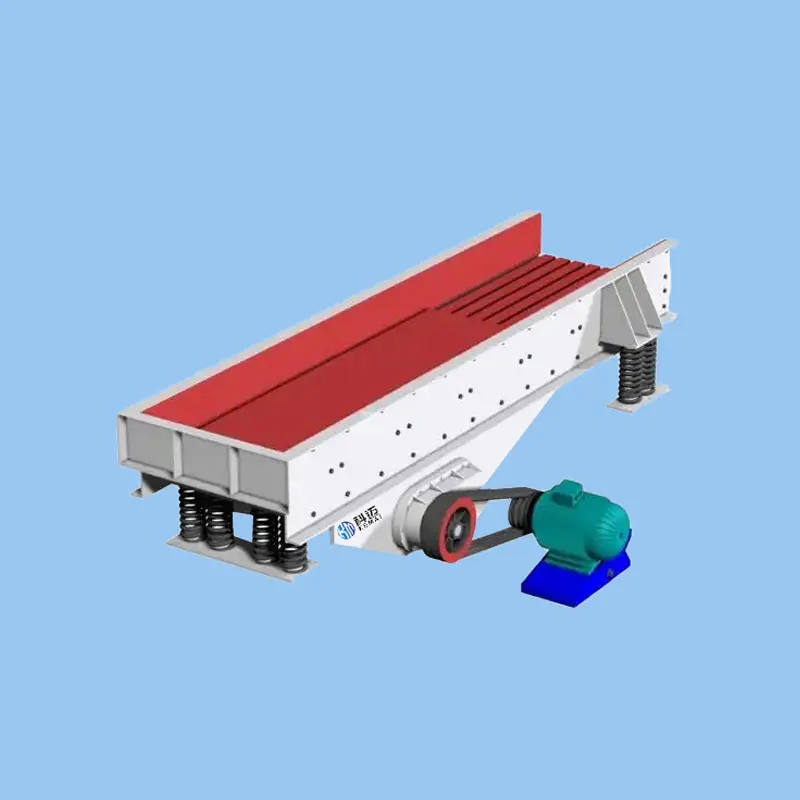

High-Quality ZSW Vibrating Feeder for Efficient Material Handling

Working Principle

The two eccentric shafts simultaneously rotate at high speed from opposite directions, and then a strong centrifugal force is produced. Along the vibrating direction, the component forces of centrifugal force will always overlap each other, and then counteract with the vertical force of vibrating direction; the exciting force along single direction is produced to drive the feeder vibrating along straight line. When materials are fed into the feeder, they will be thrown up, moving in a Para curve and falling down to the feeder. In this way, the materials move forward on the slope surface of the feeder.

Characteristic and feature of ZSW series vibrating feeder:

(1) Vibration feeder has simple structure, uniform feeding, good continuous performance and adjustable exciting force;

(2) Change and control the flow at any time, easy to operate;

(3) Eccentric block for excitation source, low noise, less power consumption, good adjustment performance, no punching phenomenon;

(4) Can adjust the exciting force, can change and control the flow at any time, easy and stable adjustment;

(5) The vibration feeder has simple structure, reliable operation, easy adjustment and installation, light weight, small size, easy maintenance, and can prevent dust pollution when the closed structure body is used.

Technical Parameters Of Pe Series Jaw Crusher

| Model | Max Feeding Size (mm) | Capacity (t/h) | Power (kW) | Overall Dimensions (L×W×H)(mm) | Machinery Weight(t) | Size of Funnel (mm) |

| ZSW-3800×960 | 500 | 90-100 | 11 | 3882×2224×2121 | 3.98 | 3800×960 |

| ZSW-4200×1100 | 580 | 200-430 | 15 | 4400×2050×1660 | 4.8 | 4200×1100 |

| ZSW-4900×1300 | 720 | 450-600 | 22 | 5200×2580×1870 | 5.9 | 4900×1300 |

| ZSW-6000×1300 | 750 | 500-700 | 30 | 6282×2580×2083 | 7.8 | 6000×1300 |

| ZSW-6000×1500 | 800 | 600-800 | 37 | 6282×2995×2083 | 8.2 | 6000×1500 |

Some Of Our Product