Analysis of common problems on cone crusher

2024-06-07

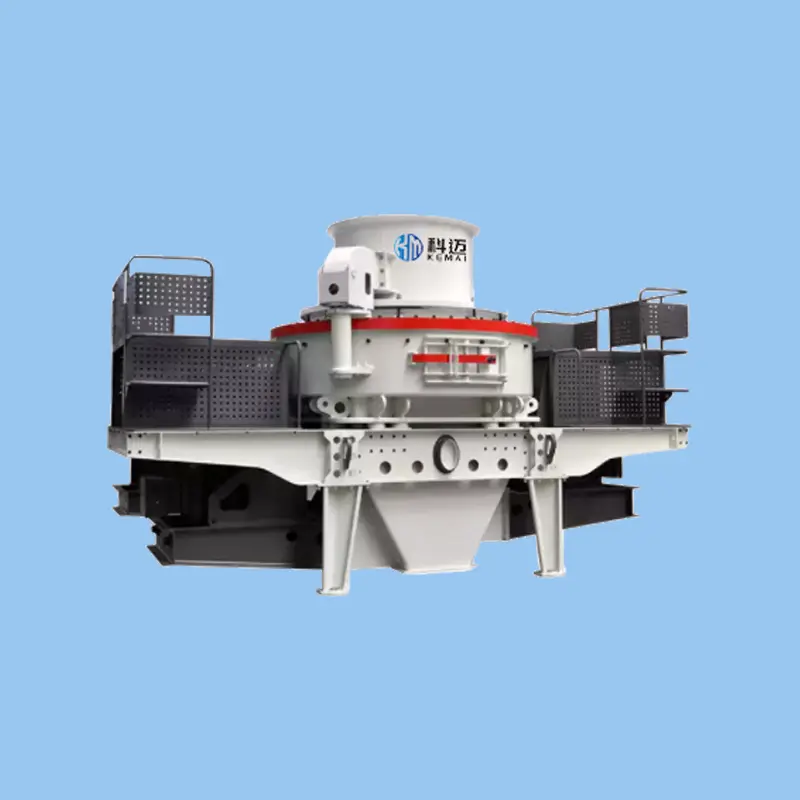

Cone Crusher is mainly used for hard mineral crushing processing ,the crushing capacity is relatively strong, and it has a high production efficiency. So the cone crusher always used in the river pebbles, basalt, iron ore and other materials in the crushing of hard materials.

Kemai machinery provides some answers towards to the common problems on the cone crusher

1.Some customers always ask why cone crusher has vibration problems,to be honest, resulting in this phenomenon for many reasons, such as:

1.1.spring tightness is not enough to feed uneven,

1.2.a lot of feed and moisture, the discharge port will cause blocking material.

These causes vibration of the cone crusher.

2.Why the tear sound appears during the crushing of ore?

This is because when the ore appears in non-broken objects, the spring of crusher plays a protective role, made of spring support ring, adjust the ring up lift and compress the spring.Increased discharge gap so that non-broken material discharged through the discharge port,when the crusher will be issued a severe impact sound, support sleeve jump, and then work properly, but in the work if iron too frequently or Large bite, it will cause spring failure, resulting in mechanical damage.

3.Why the cone crusher oil pressure increases and at the same time the oil temperature is also high?

Because the broken oil lubrication system, the oil pipe is blocked, there will be oil pressure increases at the same time oil temperature will be broken, this is also the case when the internal oil circuit is blocked.

Kemai machinery with professional technical team and first-class service for customers to create a leading domestic and foreign products,and to help customers solve all problems in the mineral crushing and grinding processing, Kemai wish to make the world a better place with continuous innovation and providing better solutions