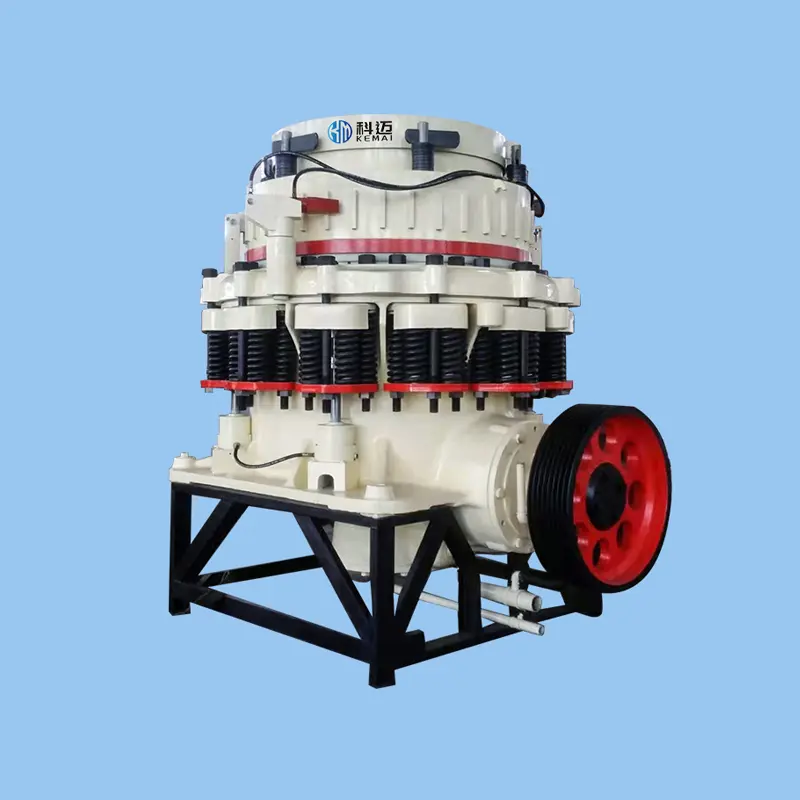

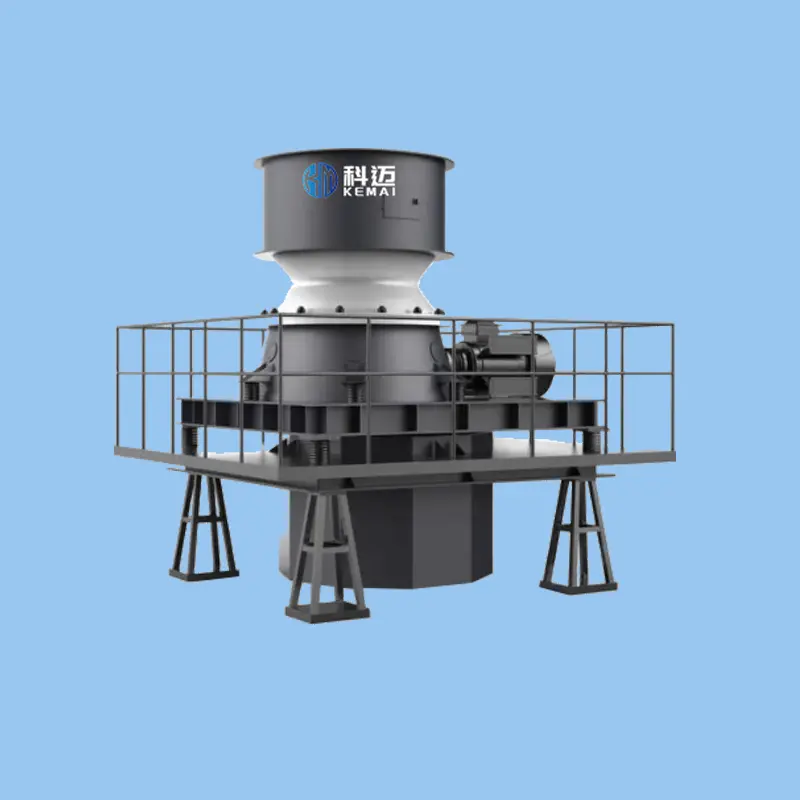

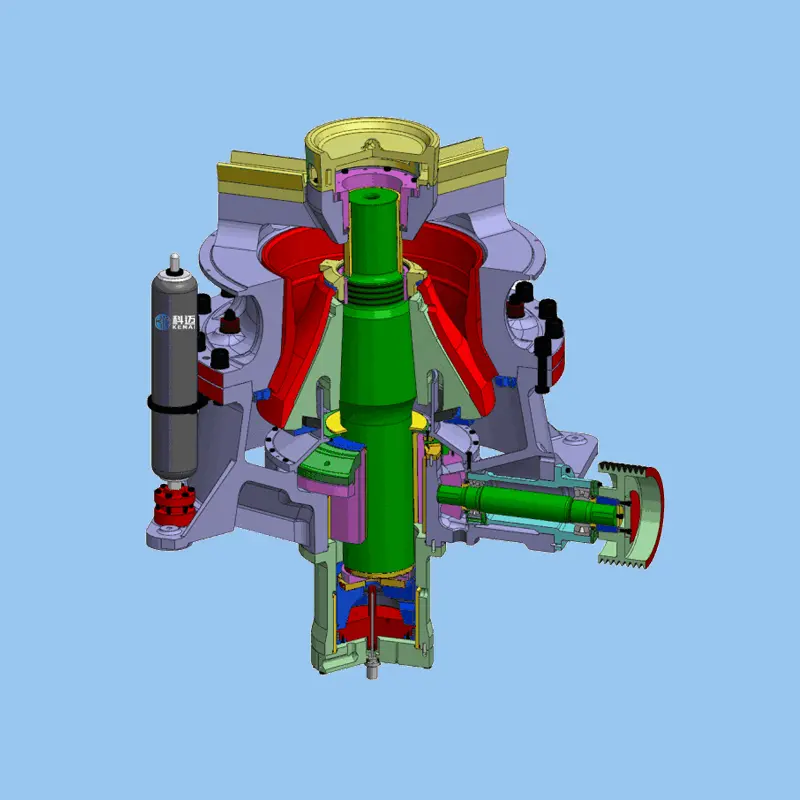

Working Principle

The motor drives the crusher pinion, the pinion drives the big gear, the big gear assembly (big gear, big gear frame, eccentric steel sleeve) drives the eccentric sleeve assembly (eccentric cylinder liner, eccentric copper sleeve) and the main shaft assembly (spindle, inner cone, inner cone liner) to the theoretical vertical line as the center, in the copper bushing revolution, the main shaft assembly in the eccentric copper sleeve to the center line of the main shaft can achieve rotation. When the air machine is running, the eccentric sleeve assembly "holds" the spindle assembly and rotates with the big gear. When the material is added to the crushing chamber, the spindle assembly (spindle, inner cone) slowly rotates in the eccentric copper sleeve under the resistance of the material. The movement of the inner cone appears to oscillate back and forth in the crushing chamber while slowly rotating. The material is crushed by the swinging inner cone. The connection between the support sleeve and the frame body is pressed tightly by the hydraulic cylinder. When the crusher falls into the metal block and other unbreakable objects, the moving cone of the single cylinder is lifted by the hydraulic piston at the bottom, which plays the role of adjustment of the discharge port and over-iron protection.

Characteristic and features

Adjustment of the size of the discharge port: The first function of the bottom hydraulic cylinder is to adjust the upper and lower positions of the spindle, thereby adjusting the spacing between the moving cone and the outer cone liner. The spacing becomes smaller, and the discharge particle size of the crusher is small; This spacing becomes larger, and the discharge particle size of the crusher is larger. At the same time, the selection of different crushing chamber types, the selection of different eccentric sleeves can also change the size of the material.

(1) Large crushing ratio and high production efficiency.

(2) Laminated crushing, the finished grain level is more uniform.

(3) Less consumption of wearing parts, low operating cost.

(4) Coarse and fine crushing can be achieved only by replacing the fixed cone.

(5) Advanced hydraulic technology realizes overload protection and hydraulic adjustment of discharge port, simplifies the crusher structure and reduces weight.

(6) Thin oil lubrication, reliable and advanced, improve service life.

(7) Easy maintenance, easy operation and use.