0102030405

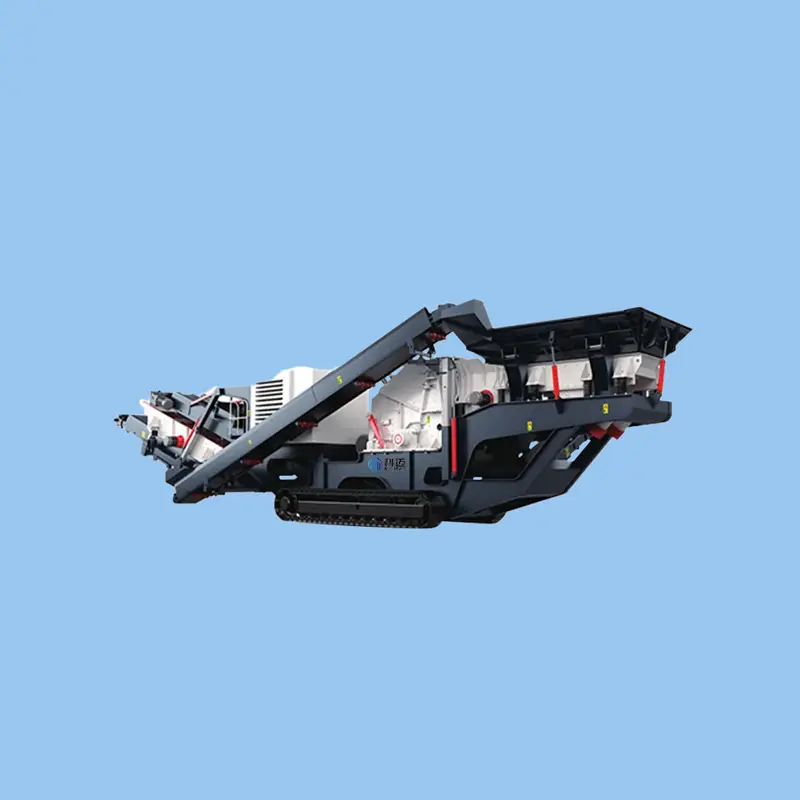

H Series Mobile Cone Crusher - Efficient and Flexible Crushing Solution

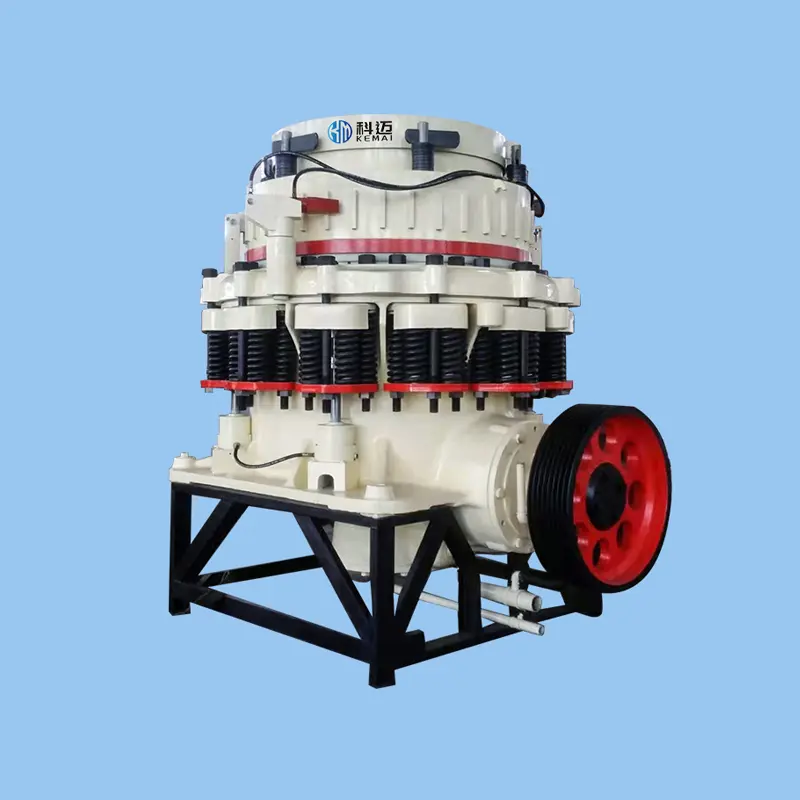

Working Principle

When the cone crusher is working, the motor rotates through the belt pulley or coupling, the cone crusher drive shaft and the cone of the cone crusher are forced to rotate around a fixed point under the eccentric sleeve. Thus, the crushing wall of the crushing cone is sometimes close to and sometimes away from the rolling wall surface fixed on the adjusting sleeve, so that the ore is constantly impacted in the crushing chamber, extrusion and bending action to achieve the crushing of the ore. The motor drives the eccentric sleeve to rotate through the bevel gear to make the crushing cone swing. The crushing cone is sometimes near and sometimes away from the fixed cone to complete the crushing and discharging. The connection between the support sleeve and the frame body is pressed by the spring, when the crusher falls into the metal block and other unbreakable objects, the spring produces compression deformation, discharge foreign matter, realize insurance, and prevent machine damage.

Characteristic and feature of H series mobile cone crusher:

1. The mobile site of the flexible tire type crushed cone mobile crushing station is high, the turning radius is small, easy to drive on the ordinary road, and more convenient to drive in the rough and harsh road environment of the crushing site: it saves time for the quick entry into the site.

It is more conducive to entering the reasonable construction area, eliminating the cumbersome steel frame structure and foundation construction when broken, saving a lot of time.

2. Reduce material costs: can directly select the site, open to the site, without transportation, directly reach the finished particle size; In addition, the extended unit can directly feed the broken material into the specific transfer belt conveyor, saving transportation costs.

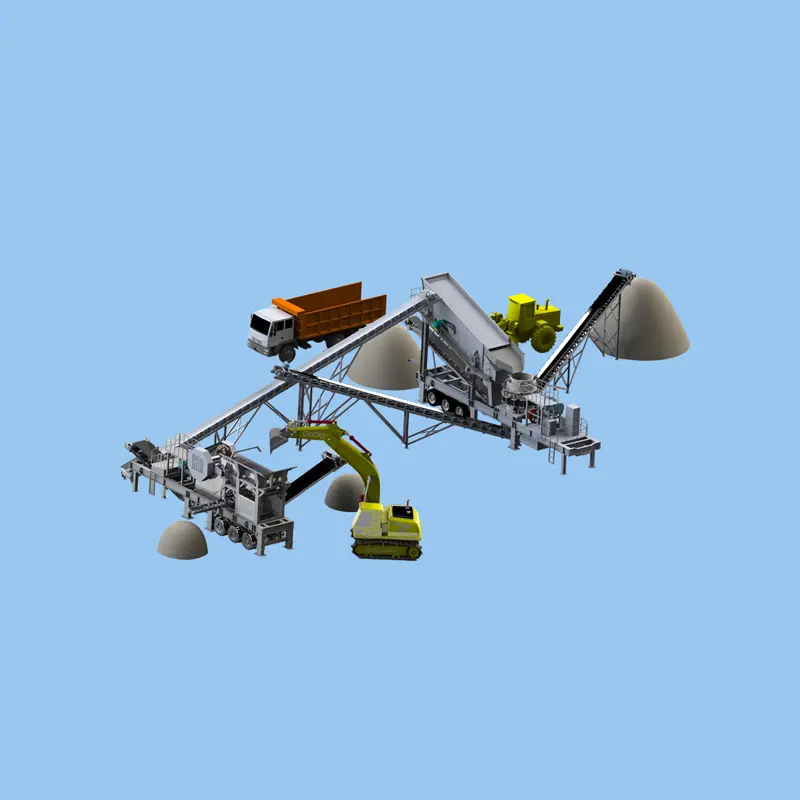

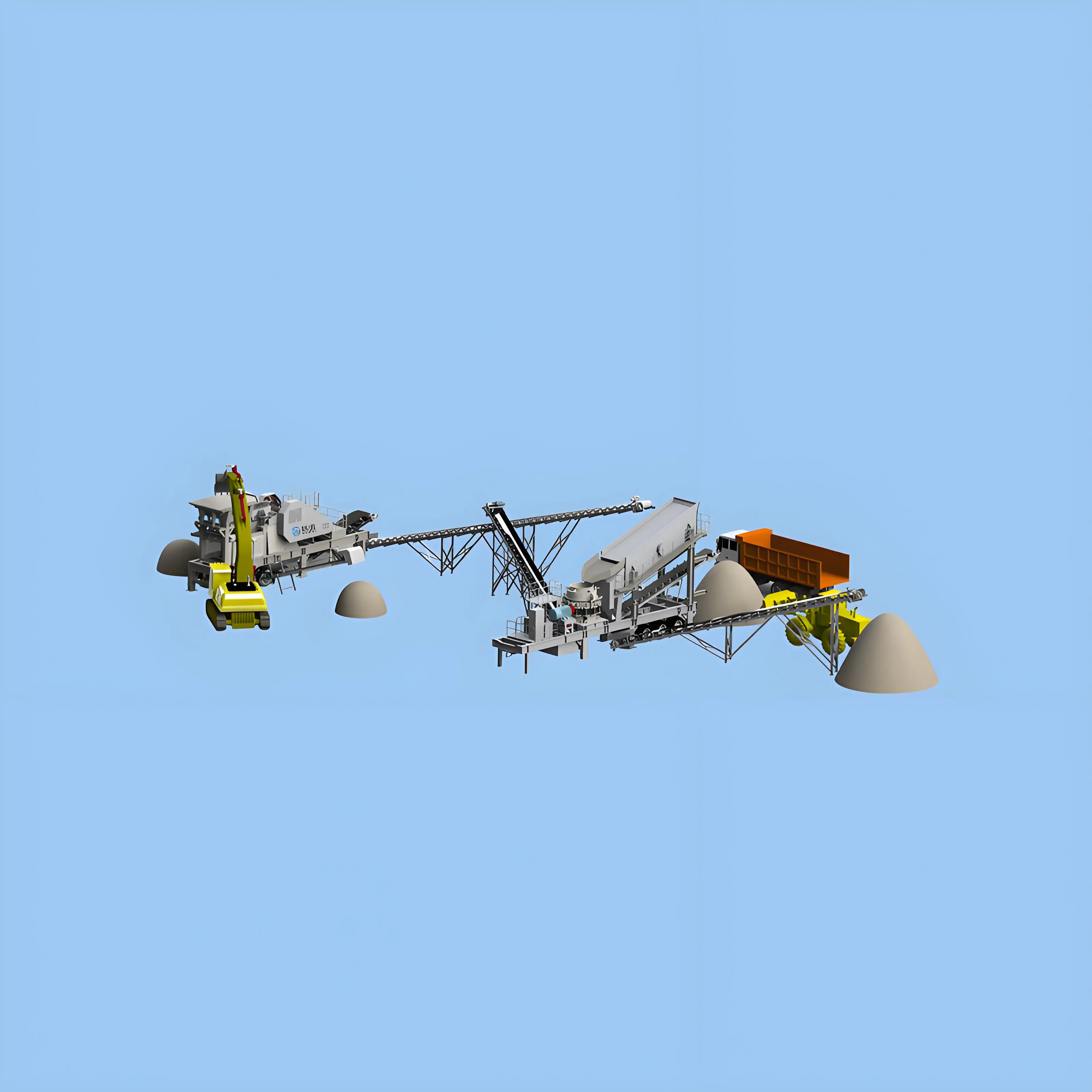

3. Direct and effective operation: integrated tire cone mobile crushing station, including primary crushing station and secondary crushing and screening station, belt conveyor, etc. Crushing station at all levels is an independent working unit, can each complete its different responsibilities, belt conveyor is responsible for the material transfer and stacking between crushing stations.

4. Strong adaptability and flexible configuration: the wheeled cone mobile crushing station provides customers with a simple and low-cost characteristic combination unit configuration. For the crushing screening system, a single unit can be operated independently, or a flexible system can be configured to operate jointly

5. Reliable performance and easy maintenance: wheeled cone mobile crushing station, equipped with high-performance cone crusher, high crushing efficiency, versatility, excellent crushing product quality, lightweight and reasonable structural design, excellent crushing performance.

Technical parameters of H series mobile cone crusher

| Model | Cone crusher model | Vibrating screen model | Max feeding size (mm) | Capacity (t/h) | Dimension (mm) |

| H-90B-1848 | CS-90B | 3YA1848 | 175 | 50-90 | 12200×2380×4590 |

| H-160B-1860 | CS-160B | 3YA1860 | 210 | 90-160 | 13200×2480×4890 |

| H-H200-1848 | HPS-200 | 3YA1848 | 185 | 60-110 | 12300×2380×4560 |

| H-H300-1860 | HPS-300 | 3YA1860 | 230 | 120-180 | 13200×2480×4890 |

Some Of Our Product