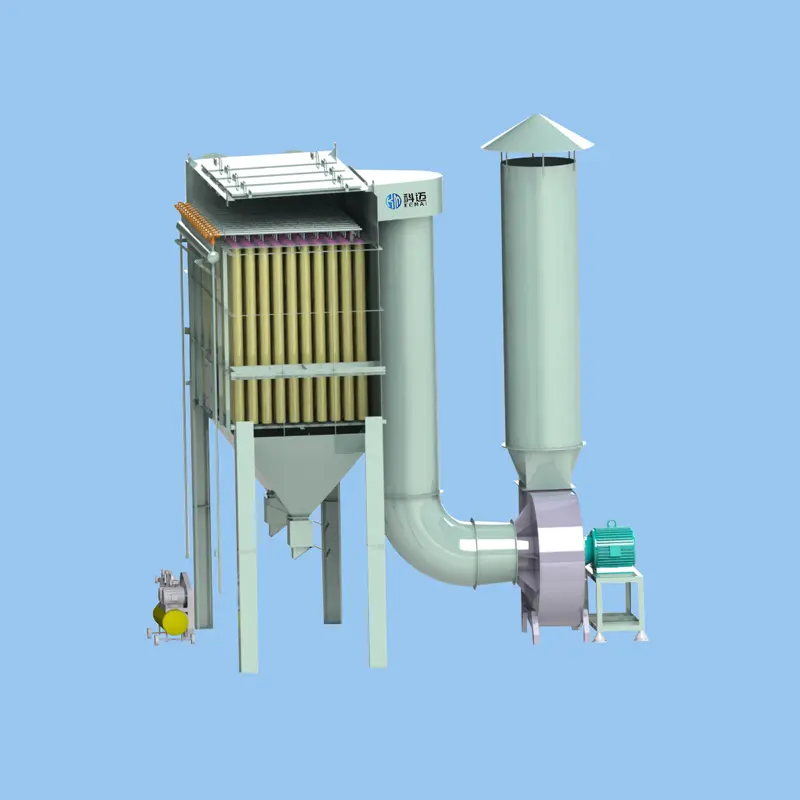

DMC Series Pulse Bag Dust Collector – Industrial Dust Collection

Working Principle

Dust-laden air enters the next ash bucket by fan powered via the inlet, then speed dips, large weight dust particles fall into the ash bucket, fine dust into the cabinet with the airflow, and out of the discharge outlet after the purification treatment by the sieve of the filter bag. The dust which separated outer of the surface of the filter bag makes the resistance increases gradually, this time the controller send up signal according to the set resistance range, electromagnetic pulse valve is open, the high-pressure air which in the air bag spray quickly, through the Venturi tube several times in the first wind-induced ambient air into the filter bag, so the filter bag instant expansion, and the dust is shaken off and falling into the dust hopper.

Technical parameters of DMC series pulse bag dust collector

| Model | Air capacity (m3.H-1) | Filter area (m2) | Wind speed (m.min-1) | Filtering bag specification (mm) | Filtering quantity | Pulse valve quantity | Air blower (kW) |

| DMC-36 | 1680~2680 | 28 | 1.0~1.6 | φ130×2000 | 36 | 6 | 2.2 |

| DMC-64 | 3060~4896 | 51 | 1.0~1.6 | φ130×2000 | 64 | 8 | 5.5 |

| DMC-80 | 12000~16800 | 80 | 2.5~3.5 | φ130×2000 | 80 | 8 | 15 |

| DMC-100 | 15600~21840 | 104 | 2.5~3.5 | φ130×2000 | 104 | 10 | 18.5 |

| DMC-120 | 18000~25200 | 120 | 2.5~3.5 | φ130×2000 | 120 | 11 | 22 |

| DMC-160 | 24000~33600 | 160 | 2.5~3.5 | φ130×2000 | 160 | 16 | 37 |

| DMC-200 | 30000~42000 | 200 | 2.5~3.5 | φ130×2000 | 200 | 20 | 45 |

| DMC-220 | 33600~47040 | 220 | 2.5~3.5 | φ130×2000 | 220 | 22 | 45 |

| DMC-260 | 39600~55440 | 260 | 2.5~3.5 | φ130×2000 | 264 | 26 | 55 |

| DMC-320 | 45600~63840 | 320 | 2.5~3.5 | φ130×2000 | 304 | 32 | 55 |

| DMC-520 | 58600~63840 | 520 | 0.8~1 | φ130×2500 | 520 | 52 | 75 |

| DMC-736 | 68600~93640 | 736 | 0.8~1 | φ130×2500 | 736 | 73 | 90 |

| DMC-900 | 109600~148000 | 900 | 0.8~1 | φ130×2500 | 900 | 90 | 110-132 |

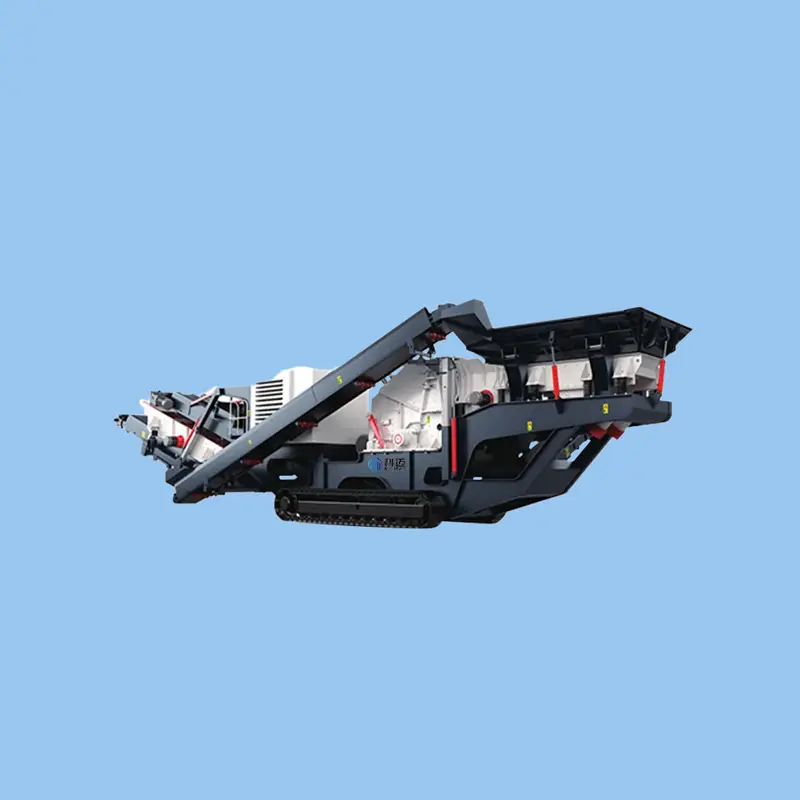

Some Of Our Product