01

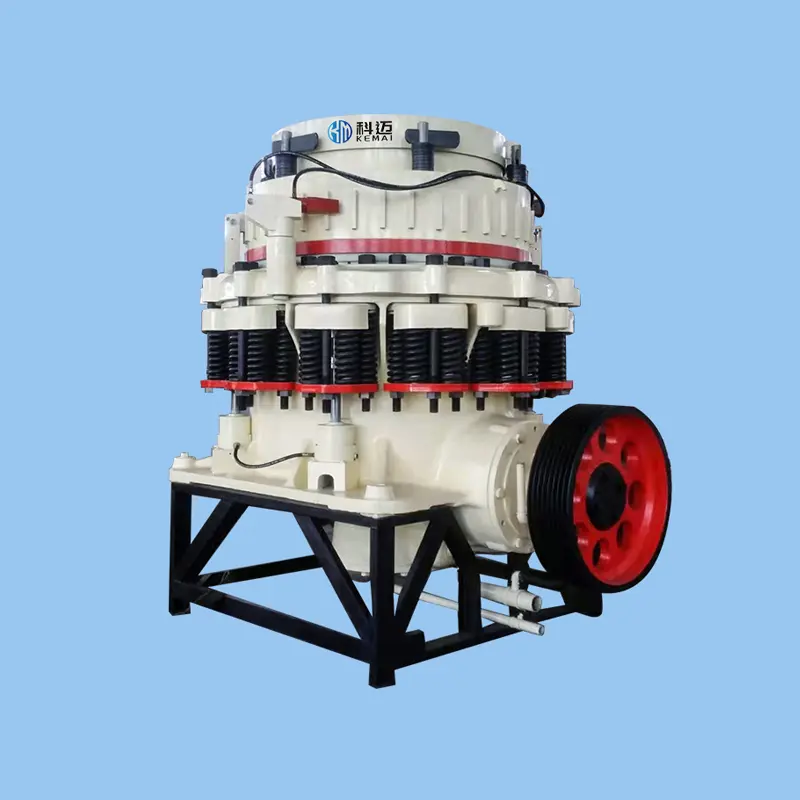

CS Series Cone Crusher: High-performance crushing solution

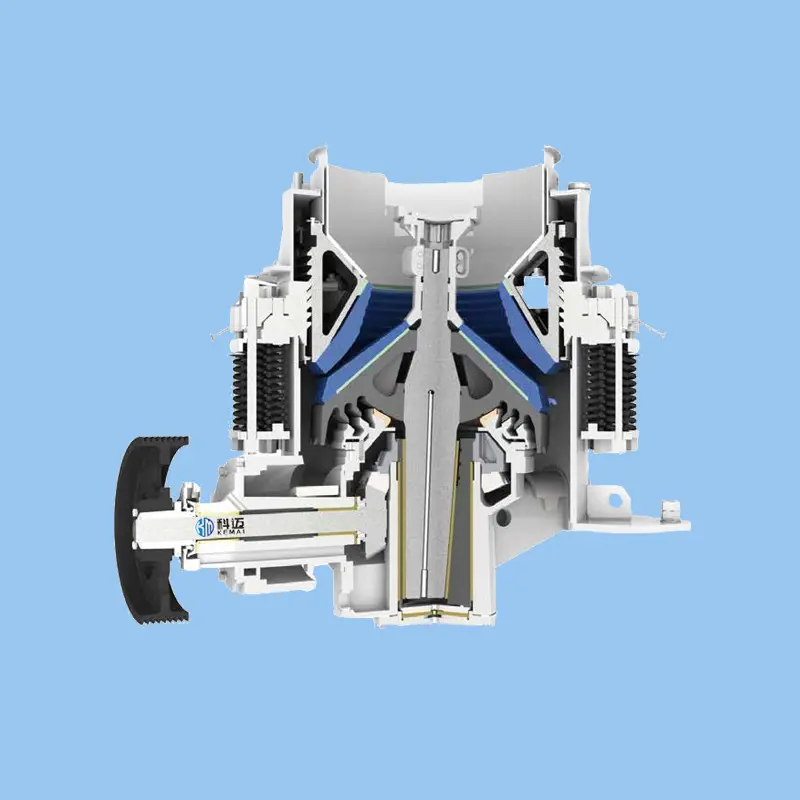

Working Principle

When working, the eccentric sleeve is driven by the motor through the triangle belt, large belt wheel, drive shaft, small bevel gear and large bevel gear, and the broken cone axis line rotates and moves under the forced action of the eccentric shaft sleeve, so that the surface of the broken wall is sometimes close to and sometimes away from the surface of the rolling wall. Thus, the material is constantly crushed by extrusion impact and bending in the ring crushing chamber composed of moving cone. After many times of extrusion impact and bending, the material is broken to the required particle size and discharged through the lower part.

Features And Characteristic

1. The product particle size composition is good: using the principle of laminating crushing, so that the proportion of cubes in the product is significantly increased, the needle flake stone is reduced, and the particle size is more uniform.

2. Good stability: when there is an iron block and other non-broken into the machine, the iron protection device will automatically release it, and then automatically reset. The over-iron protection has a fixed discharge port return point, and the original discharge port can be quickly restored after the impurity iron passes through the crushing chamber.

3. Cavity cleaning is convenient: if the spring cone crusher is shut down under load, the hydraulic cavity cleaning system can quickly clean the crushing cavity, greatly reducing the downtime.

4. High reliability: the use of large diameter spindle, heavy main frame and independent thin oil lubrication system of automatic control system, to ensure that the equipment durable, reliable operation.

5. Easy maintenance and easy operation: all parts can be removed from the upper or side, so that the fixed cone and moving cone assembly can be easily removed. Bronze plain bearings can maintain excellent load bearing performance in high impact vibration crushing environment, and are more economical and convenient to maintain than rolling bearings.

6. Low production cost: due to large production capacity, high reliability, convenient maintenance, greatly reduce the production cost.

7. Separate lubrication: multi-point control of independent thin oil lubrication system, can ensure the double protection of bearing lubrication, and can achieve automatic safety protection of the whole machine.

Technical parameters of CS series cone crusher ( standard )

| Type | Cavity | Feed opening (mm) | Discharge setting (mm) | Capacity (t/h) | Power (kW) | Weight (t) | Overall dimension (mm) |

| CS-90B (3 ft) |

Fine | 102 | 9-22 | 45-91 | 75 | 15 | 2656x1746x2241 |

| Coarse | 175 | 13-38 | 59-163 | ||||

| Extra coarse | 178 | 25-38 | 118-163 | ||||

| CS-160B (4 1/4 ft) |

Fine | 137 | 13-31 | 109-181 | 155 | 27 | 2809x2354x3156 |

| Medium | 210 | 16-38 | 132-253 | ||||

| Coarse | 241 | 19-51 | 172-349 | ||||

| Extra | 259 | 25-51 | 236-358 | ||||

| CS-250B (5 1/2 ft) |

Fine | 209 | 16-38 | 181-327 | 250 | 55 | 3911x2870x3771 |

| Medium | 241 | 22-51 | 258-417 | ||||

| Coarse | 269 | 25-64 | 299-635 | ||||

| Extra | 368 | 38-64 | 431-630 | ||||

| CS-315B (7 ft) |

Fine | 278 | 19-38 | 381-726 | 315 | 110 | 4613x3251x4732 |

| Medium | 334 | 25-51 | 608-998 | ||||

| Coarse | 369 | 31-64 | 789-1270 | ||||

| Extra | 460 | 38-64 | 880-1361 |

Technical parameters of CS series cone crusher ( Short head )

| Type | Cavity | Feed opening (mm) | Discharge setting (mm) | Capacity (t/h) | Power (kW) | Weight (t) | Overall dimension (mm) |

| CS-90D (3 ft) |

Fine | 41 | 3-13 | 27-90 | 75 | 15 | 2656x1746x2410 |

| Coarse | 60 | 3-16 | 27-100 | ||||

| Extra coarse | 76 | 6-19 | 59-127 | ||||

| CS-160D (4 1/4 ft) |

Fine | 64 | 3-16 | 36-163 | 155 | 27 | 2958x2254x3156 |

| Medium | 89 | 6-16 | 82-163 | ||||

| Coarse | 105 | 10-25 | 109-227 | ||||

| Extra | 133 | 19-25 | 209-236 | ||||

| CS-250D (5 1/2 ft) |

Fine | 70 | 5-13 | 90-209 | 220 | 55 | 3917x2870x3771 |

| Medium | 89 | 6-19 | 136-281 | ||||

| Coarse | 133 | 10-25 | 190-336 | ||||

| Extra | 133 | 10-25 | 253-336 | ||||

| CS-315D (7 ft) |

Fine | 105 | 5-16 | 190-408 | 315 | 110 | 4130x3251x4454 |

| Medium | 133 | 10-19 | 354-508 | ||||

| Coarse | 178 | 13-25 | 454-599 | ||||

| Extra | 203 | 16-25 | 508-653 |

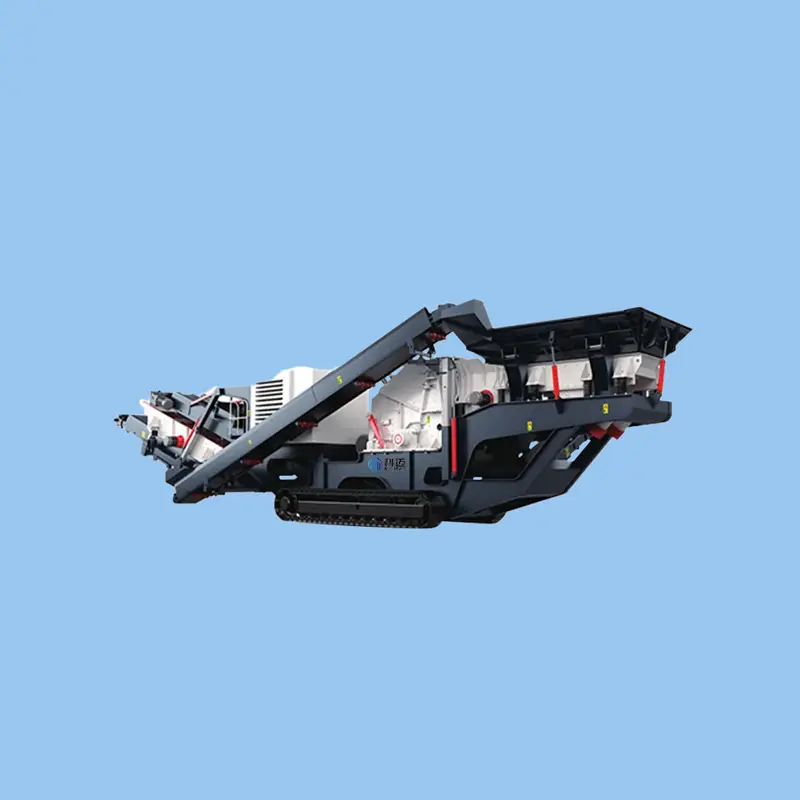

Some Of Our Product