0102030405

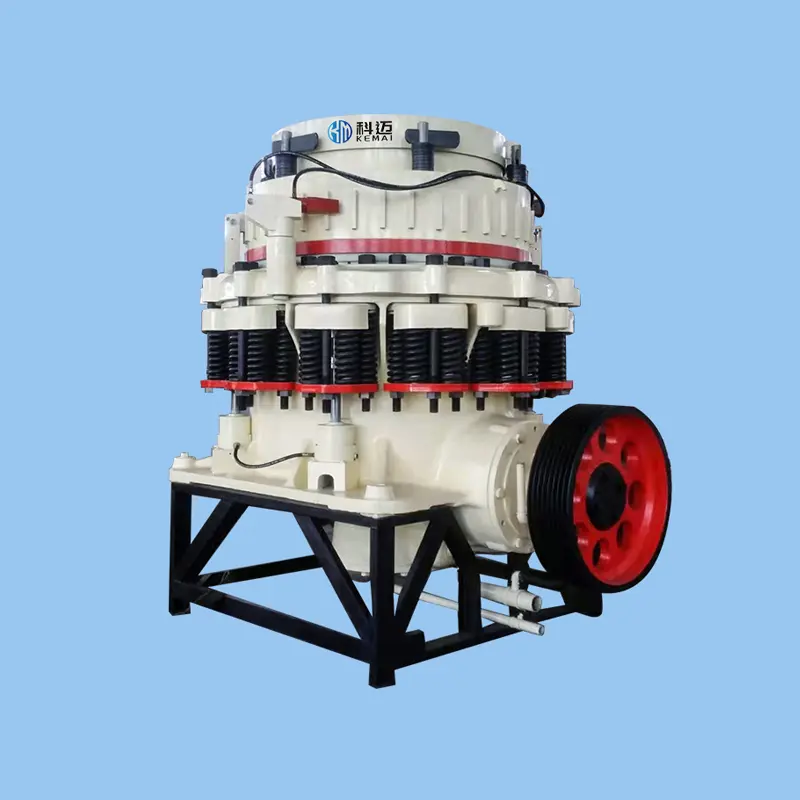

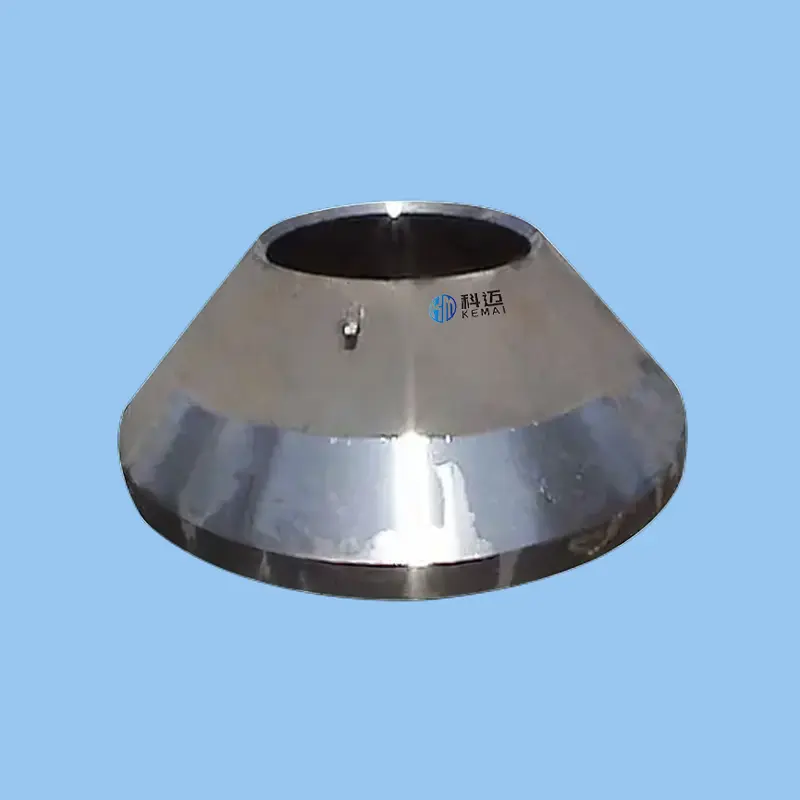

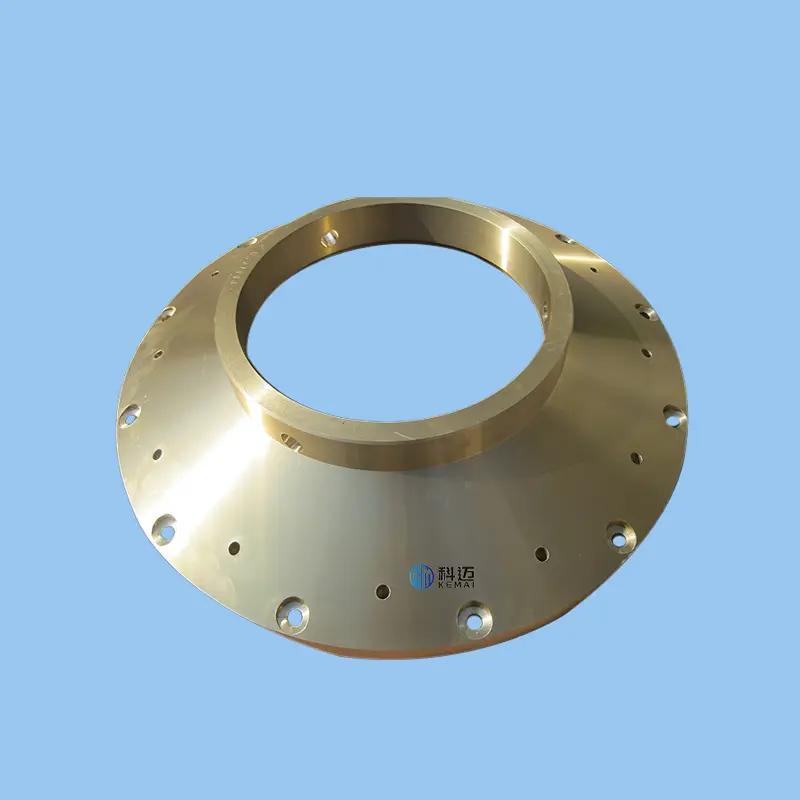

Cone Crusher Spare Parts - Affordable Quality

Working Principle

From the working principle, the crushing of the material mainly depends on the extrusion between the bowler liner and mantle to achieve the processing effect, so the wear resistance of the cone and mantle will directly determine the service performance and service life of the cone crusher. Increasing the wear resistance of the cone and mantle can make the broken material more uniform, and can slow the wear of the cone and mantle, and save processing costs for the processing manufacturers. From another point of view, if the abrasion resistance of the bowl liner and mantle l is relatively good, the replacement cycle is relatively long, and the frequency of suspending production and processing due to the replacement of these parts is low, which can help uninterrupted production and processing and improve efficiency.

Characteristic and feature of cone (bowl liner) and mantle:

1. High strength: the rolled mortar wall is made of high-strength material, which can withstand high-power crushing force and ensure the stability and durability of the equipment.

2. Wear resistance: After special treatment, the surface of the rolled mortar wall has high wear resistance, which can be used for a long time and is not easy to wear, reduce the frequency of replacement parts and reduce operating costs.

3. Impact resistance: the structural design of the rolled mortar wall can withstand the role of large impact, ensure that the equipment is not easy to damage when breaking hard materials, and improve the service life of the equipment.

4. Energy saving and environmental protection: The rolled mortar wall adopts advanced crushing technology, which can achieve full crushing and screening of materials, improve production efficiency, and reduce noise and dust generation, which is conducive to energy saving and environmental protection.

Technical parameters of cone (bowl liner) and mantle

| Material code | C | Mn | Si | Cr | P | S |

| Mn13Cr2 | 1.0-1.3 | 11-14 | 0.3-0.6 | 1.7-2.4 | ≤0.05 | ≤0.03 |

| Mn18Cr2 | 1.1-1.4 | 17-20 | 0.3-0.6 | 1.7-2.4 | ≤0.05 | ≤0.03 |

| Mn22Cr2 | 1.1-1.4 | 20-24 | 0.3-0.6 | 1.7-2.4 | ≤0.05 | ≤0.03 |

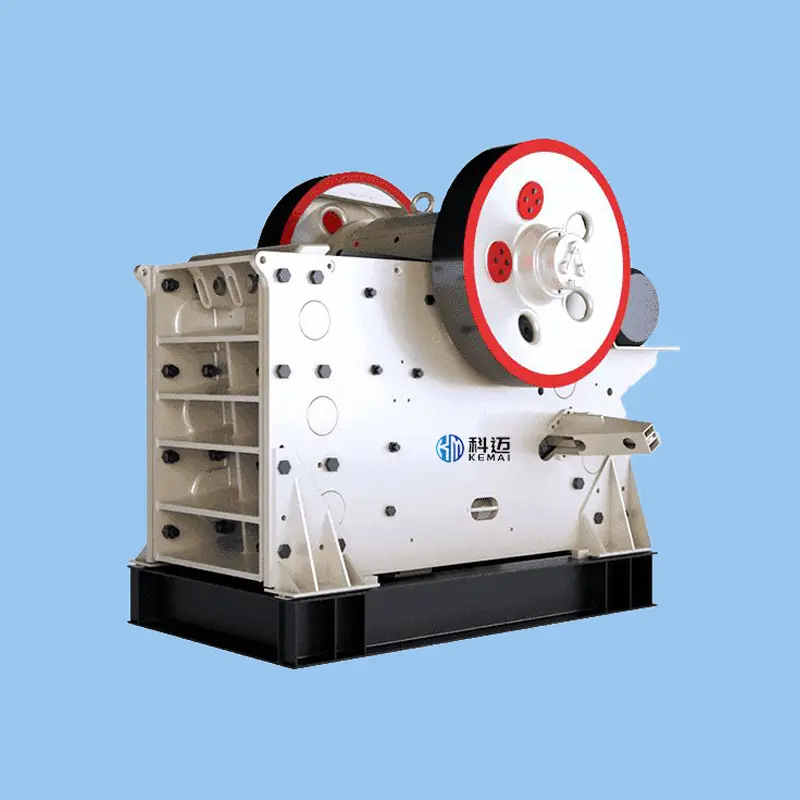

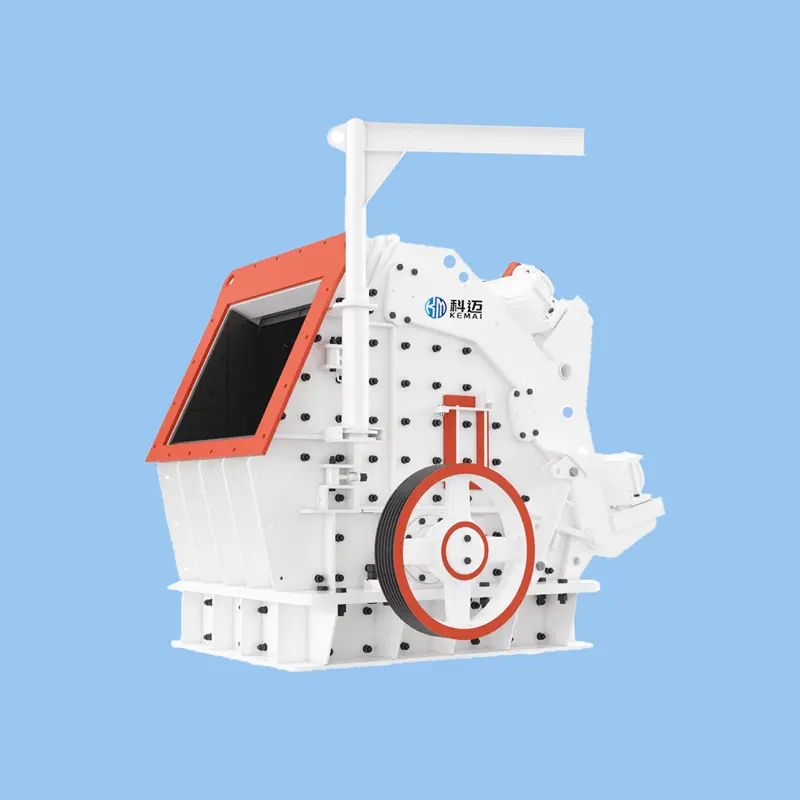

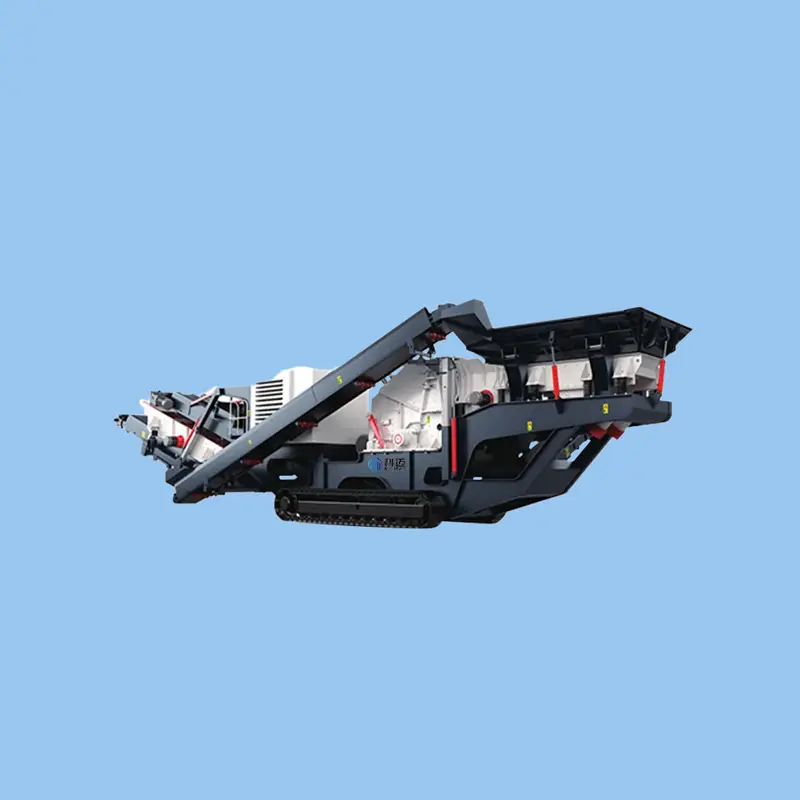

Some Of Our Product