01

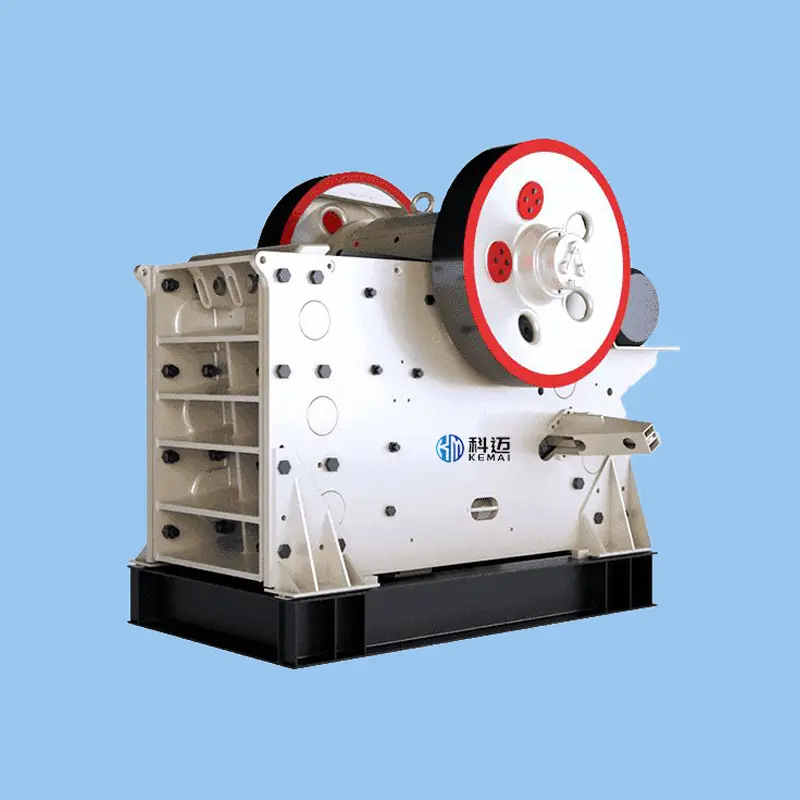

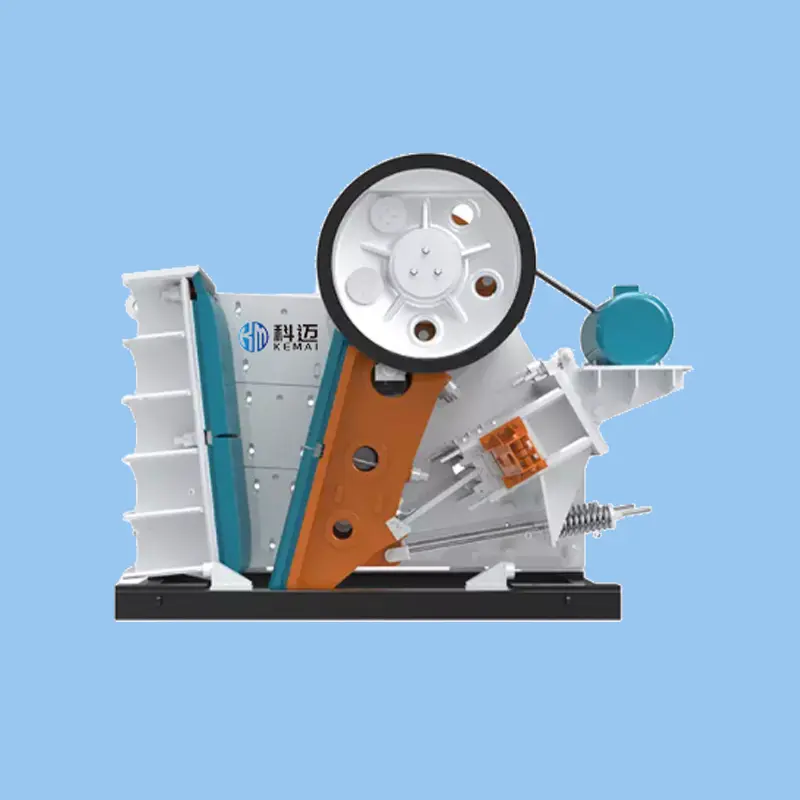

C Series Jaw Crusher: Advanced Crushing Technology

Working Principle

1.Application of modular construction and no-welding designs remove stress concentration and improve the service life. If it is difficult to transport or install the whole machine on the site, the frame construction series jaw crusher can be disassembled and then installed that reduces the freight and installation cost.

2.After long-term operation, the parts of jaw crusher are easier to be checked and replaced than those of welding or casting structures, which reduces the maintenance and operation cost.

3.The front plate, movable jaw plate, back plate, bearing base and other parts are made of high quality cast steel. Heavy eccentric shaft is made of high alloy steels with process of smithing, fault detection, impact extrusion and other special techniques. Four aligning roller bearing and high performance dustproof sealing resist the impulse load and severe atmosphere.

4.The adjusting system of jaw crusher adopts shim block structure, staff gauge and special gear system to simplify the adjustment of discharge opening.

5.The belt wheel of motor adopts probe-drogue connection to simplify the maintenance. Customers can use their needed belt wheel to meet their capacity.

6.Integrated motor and main frame structure save the space, shorten the length of V-belt and reduce vibration of V-belt so that the life of V-belt will be longer.

7.Jaw plates are made of high manganese steels with metallographic checking. The connection of jaw plates are processed with mechanical workout. All of these improve the crushing ratio.

8.Guide chute ensures the material to be fed in to the crushing cavity. It is not necessary to remove the guide chute while replacing the jaw plates.

9.It is easy to unload the guide chute in other maintenance. The protective cover avoids the materials splashing, protects the workers and facilitates the supervision of operation.

Technical Parameters Of Pe Series Jaw Crusher

| Model | C96 | C110 | C125 | C140 | |

| Feeding opening size(mm) | 600×900 | 750×1060 | 950×1250 | 1070×1400 | |

| Max feeding size (mm) | 500 | 630 | 800 | 900 | |

| Motor power( KW) | 90 | 110 | 132/160 | 185/200 | |

| Product size(mm) | Discharge size(mm) | Capacity (T/h) | Capacity (T/h) | Capacity (T/h) | Capacity (T/h) |

| 0-90 | 60 | 120-155 | |||

| 0-105 | 70 | 140-180 | 150-195 | ||

| 0-120 | 80 | 160-210 | 170-225 | ||

| 0-135 | 90 | 180-235 | 190-245 | ||

| 0-150 | 100 | 200-255 | 215-280 | 290-380 | |

| 0-185 | 125 | 250-320 | 265-345 | 350-455 | 385-500 |

| 0-225 | 150 | 300-380 | 315-410 | 410-535 | 455-590 |

| 0-260 | 175 | 330-440 | 370-480 | 470-610 | 520-675 |

| 0-300 | 200 | 420-545 | 530-690 | 590-765 | |

| 0-340 | 225 | 590-770 | 655-850 | ||

| 0-375 | 250 | 650-845 | 725-945 |

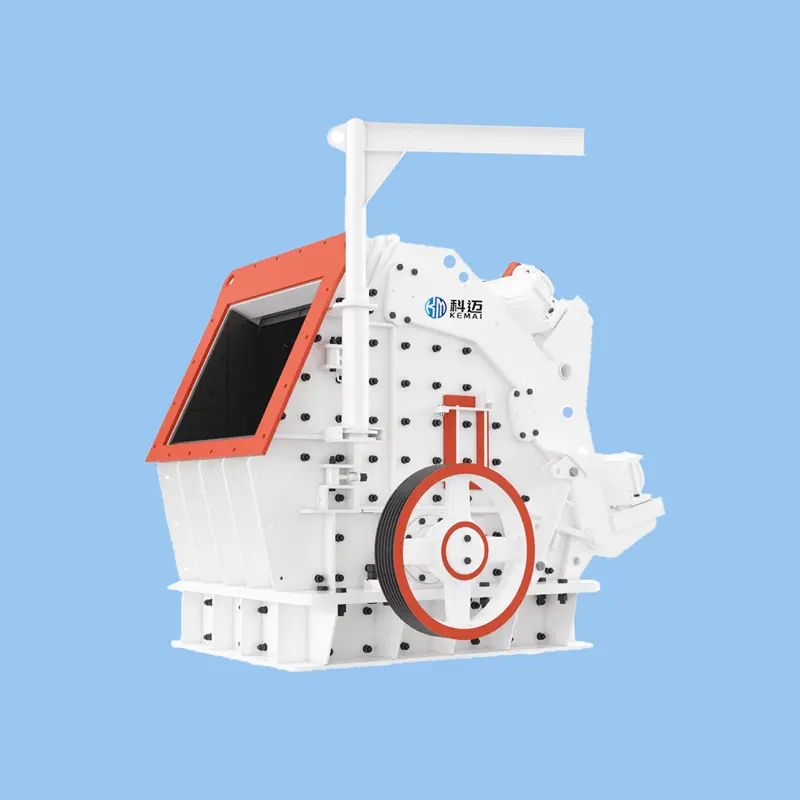

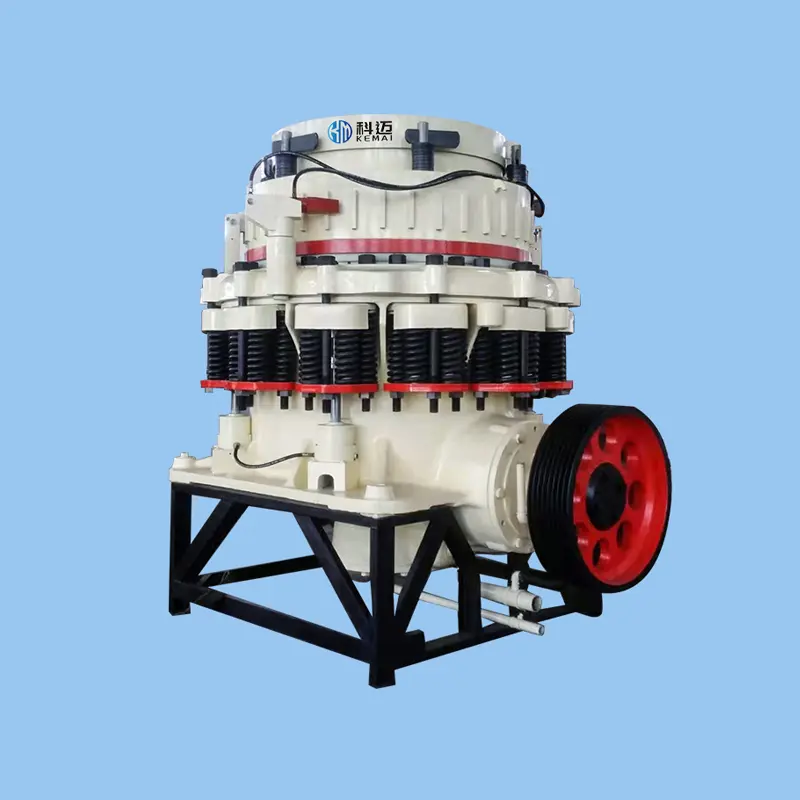

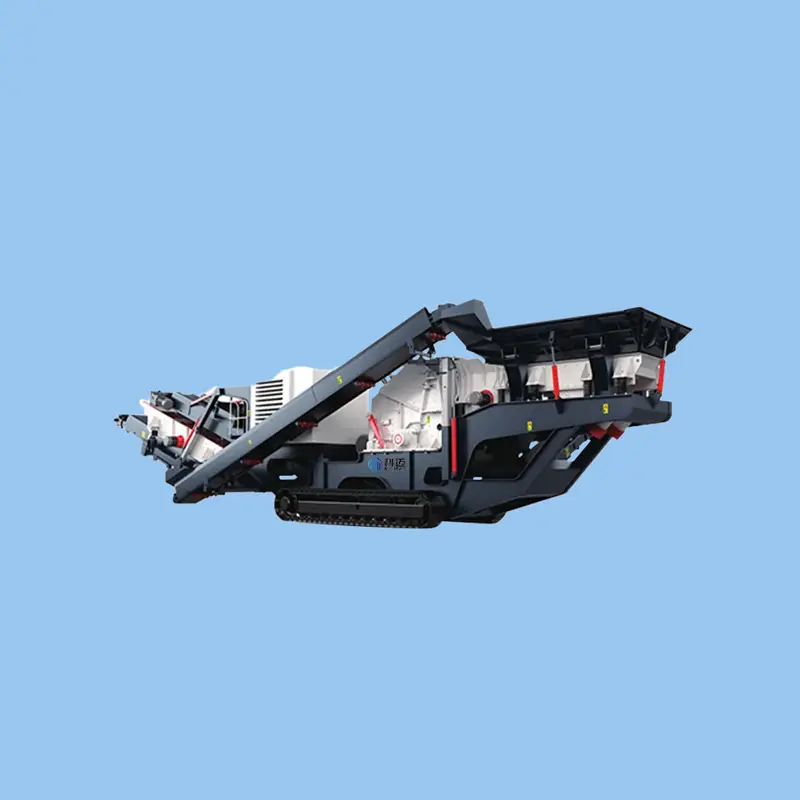

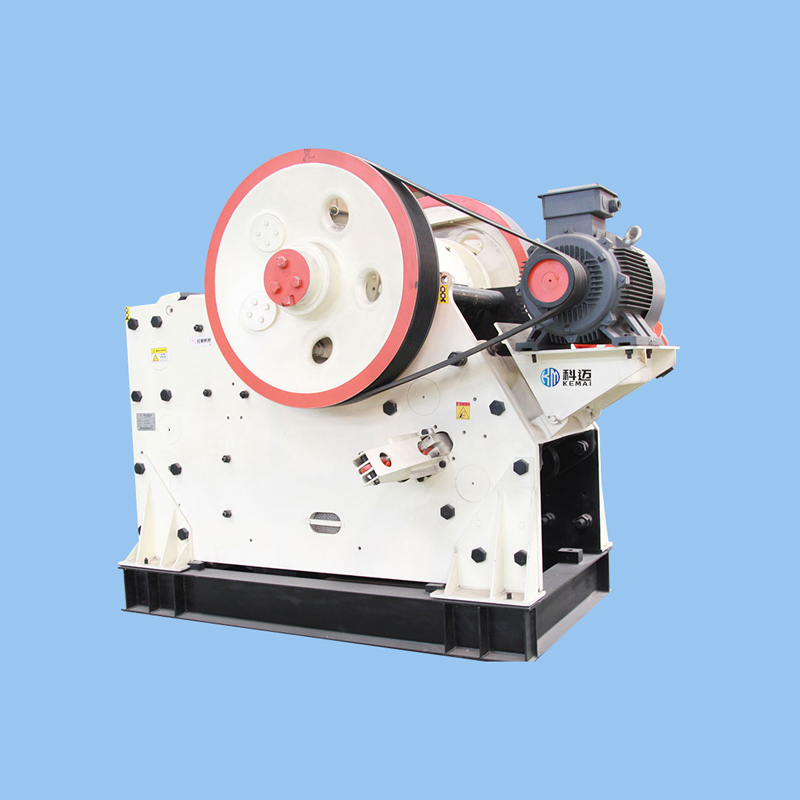

Some Of Our Product