Choosing the right Bentonite Crusher is crucial for any project involving this mineral. Bentonite is widely used in industries like construction, drilling, and agriculture. However, not all crushers are created equal. Selecting the correct model can enhance efficiency and productivity.

When evaluating your options, consider factors such as capacity, size, and power requirements. Think about the type of bentonite you'll be processing. There are various grades of bentonite, each needing different crushing techniques. It’s essential to match the crusher with your specific needs to avoid inefficiencies.

Moreover, pay attention to the maintenance requirements of the Bentonite Crusher. Some models can be challenging to service. This may lead to downtime, which could impact your overall operations. Finding the right balance between performance and easy maintenance is a task worth contemplating. Evaluate, reflect, and ask the right questions to make a wise choice.

Bentonite crushers play a crucial role in various industries, from

construction to agriculture. These machines process bentonite clay, which is essential for

oil drilling, foundry work, and more. The effectiveness of the crusher can greatly impact the quality of the final product.

A good crusher ensures uniformity and consistency. This improves the performance in applications.

Selecting the right bentonite crusher can be challenging. There are numerous factors to consider, such as size, output, and maintenance. It's important to analyze specific needs before making a decision.

Often, what seems to work well on paper does not translate in real-world applications. Understanding the characteristics of your materials helps in choosing the best model.

However, some may overlook the importance of ongoing evaluation. As production needs change, so should the equipment.

Regular feedback from operators provides valuable insights. This can highlight when a crusher is underperforming or when it's time for an upgrade.

Finding the perfect fit is an ongoing process. Balancing cost and efficiency requires careful consideration.

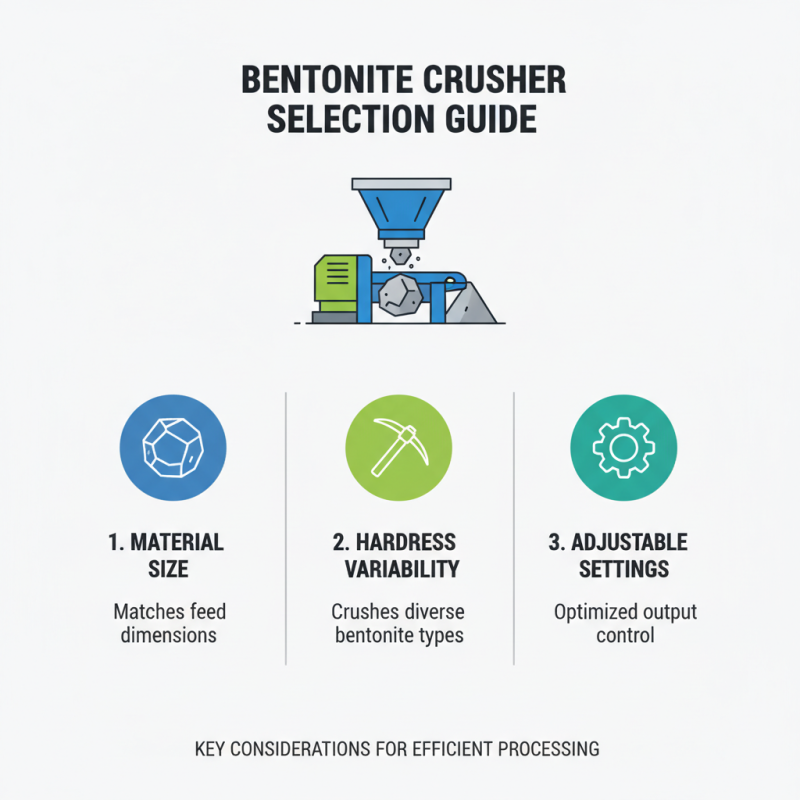

When selecting a bentonite crusher, consider the size of the material you need to process. Bentonite varies in hardness. A crusher should effectively handle the specific type of bentonite you use. Look for machines that offer adjustable settings. This flexibility can be crucial for getting the desired output.

Next, evaluate the crusher's production capacity. Depending on your requirements, you may need a high-capacity machine. It's essential to balance speed and efficiency. Don't overlook the maintenance aspect. A crusher that is hard to maintain may lead to downtime, impacting productivity.

Another factor is the energy consumption. Some machines may promise high efficiency but use more energy in the process. Analyze the cost-effectiveness over time. Often, the cheapest option can lead to increased expenses later. Reflect on your long-term needs and operational costs before making a final decision.

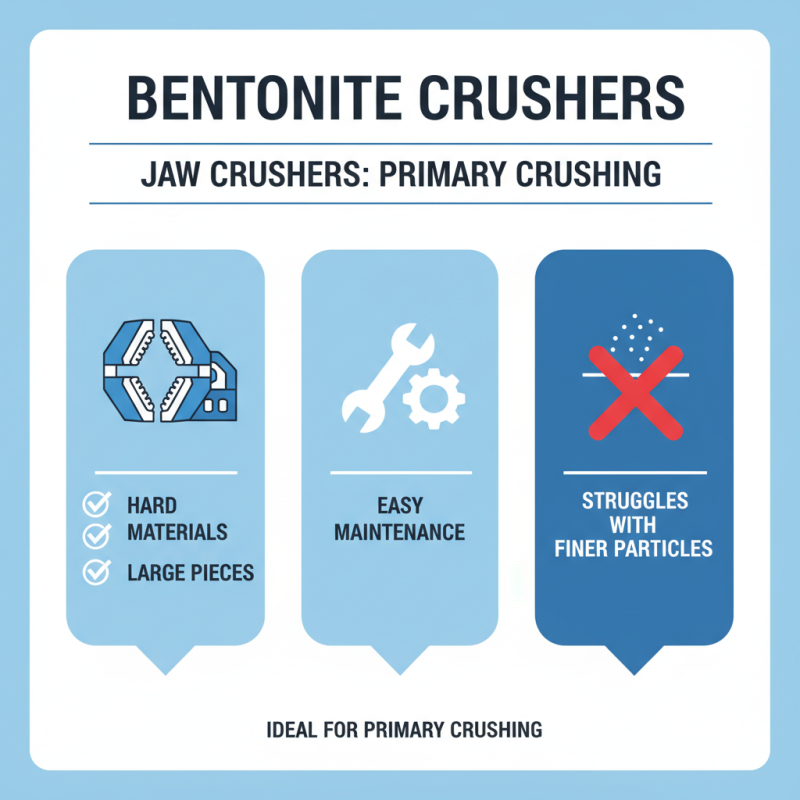

When choosing a bentonite crusher, understanding the different types is essential. Jaw crushers are common. They are ideal for primary crushing. They handle hard materials, making them suitable for larger pieces of bentonite. The design allows for easy maintenance. However, they might struggle with finer particles.

On the other hand, impact crushers provide a different solution. They excel at producing finer material. The high-speed impact shatters the bentonite. This method is more effective for medium to soft materials. Choosing between these options depends on the desired final product.

Roll crushers are another variation. They compress the material between two rotating rolls. This design is efficient for uniform particle size. Still, it might not be suitable for very hard bentonite. You may need to experiment with different types. Each has its advantages and drawbacks. Understanding these details can lead to better outcomes.

When choosing a bentonite crusher, evaluating performance and efficiency is paramount. You want a machine that can process materials effectively. Start by examining the crushing capacity. It should meet your production needs. Pay attention to the size reduction ratio. A higher ratio means more efficient processing of raw material.

Consider the energy consumption as well. Crushers can be power-hungry. Look for models that balance productivity with lower energy costs. Maintenance is another critical aspect. Some machines require frequent servicing, leading to more downtime. Always factor in how easy it is to access parts for maintenance.

Don’t overlook the importance of feedback from users. Real-world performance can differ from manufacturer claims. Look into case studies or user reviews. These insights reveal potential pitfalls. Remember, the best choice often hinges on specific operational needs and conditions. Sometimes, too much information can lead to confusion. Take a step back and assess what is most vital for your operation.

| Model | Capacity (tons/hour) | Motor Power (kW) | Efficiency (%) | Weight (kg) |

|---|---|---|---|---|

| Model A | 50 | 75 | 90 | 1200 |

| Model B | 75 | 100 | 88 | 1500 |

| Model C | 100 | 150 | 85 | 2000 |

| Model D | 65 | 90 | 92 | 1600 |

| Model E | 80 | 110 | 87 | 1800 |

When it comes to maintaining your bentonite crusher, regular checks are essential. Inspecting the wear parts can prevent costly breakdowns. You should also monitor the lubrication system. Proper lubrication reduces friction and wear, extending the machine's lifespan.

Another important aspect is keeping the crusher clean. Dust and debris can accumulate, affecting performance. A clean machine runs more efficiently. Additionally, ensure that all bolts and screws are tight. Loose components can lead to vibrations, which may cause damage over time.

Training operators on safe handling practices is crucial. Human error can lead to unnecessary wear. Regular training sessions can enhance awareness. Pay attention to any unusual noises during operation. Early detection of issues can save time and money. Small changes today can make a big difference tomorrow.