In the ever-evolving construction and mining industries, the demand for efficient and versatile equipment has paved the way for the increasing popularity of Portable Crushers. These machines are designed to crush various materials on-site, providing a tremendous advantage in terms of mobility and operational efficiency. As we approach 2025, understanding the key trends shaping the Portable Crusher market becomes pivotal for stakeholders aiming to make informed purchasing decisions.

In upcoming sections, we will explore essential features and advancements in Portable Crushers, including innovations that enhance performance and streamline operations. Additionally, considerations such as size, weight, and output capacity will play crucial roles in determining the best fit for specific needs. By examining these trends, potential buyers will be equipped with the insights needed to navigate the complexities of selecting a Portable Crusher tailored to their requirements, ensuring they can capitalize on the benefits this equipment offers in today's fast-paced environment.

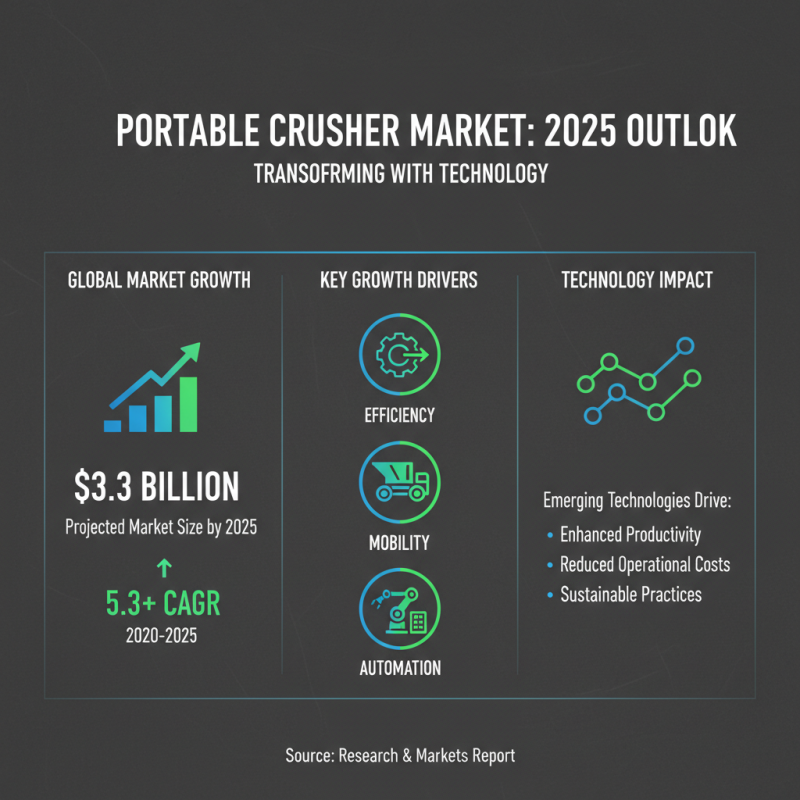

As we look towards 2025, the portable crusher market is witnessing a significant transformation driven by emerging technologies. According to a report by Research and Markets, the global mobile crushers and screeners market is projected to reach $3.3 billion by 2025, growing at a CAGR of over 5.3% from 2020. This growth is heavily influenced by advances in efficiency, mobility, and automation within portable crushing systems.

One of the most notable trends is the integration of artificial intelligence (AI) and machine learning capabilities into portable crushers. These technologies allow for enhanced operational efficiency and predictive maintenance, minimizing downtime and reducing operational costs. Additionally, innovations in hybrid and fully electric models are making these machines more sustainable, aligning with industry shifts towards eco-friendly solutions. A report from MarketsandMarkets indicates that the demand for eco-friendly construction equipment is expected to surge, with fuel-efficient portable crushers leading the charge in reducing carbon footprints on job sites.

Furthermore, advancements in material science are contributing to lighter, yet more durable portable crushers, improving not just performance but also transport logistics. Higher crushing capacities paired with reduced weights enable operators to maximize their productivity without sacrificing mobility. As companies strive for more versatile machinery, the adoption of modular designs that allow for easy upgrades and customization is expected to become commonplace in portable crusher offerings.

When selecting a portable crusher, several key features should be at the forefront of your decision-making process. First and foremost, consider the crusher’s capacity and size. It’s essential to choose a model that aligns with your production requirements while offering flexibility and mobility for various job sites. Assess the input and output dimensions to ensure that the crusher can handle the materials effectively and provide the desired size reduction.

Another critical feature is the power source. Portable crushers are available with electric or diesel options, each having its advantages and implications for job site accessibility and operational efficiency. Electric models tend to have lower operating costs and reduced emissions, while diesel units offer greater mobility and autonomy, especially in remote locations. Additionally, examining the durability and construction of the portable crusher will help you determine its suitability for rugged environments, ensuring that the machine can withstand regular wear and tear without compromising performance.

Lastly, ease of maintenance and availability of spare parts are factors that should not be overlooked. A user-friendly design can significantly reduce downtime during operation, so look for features that facilitate quick access to components. Ensuring that parts and service support are easily accessible can contribute to the longevity and efficiency of your investment in a portable crusher.

As the demand for portable crushers continues to grow, several market trends are shaping the landscape in 2025. One significant trend is the increasing focus on sustainability and eco-friendly practices. Many companies are now seeking equipment that minimizes environmental impact while maintaining efficiency. This shift is encouraging manufacturers to innovate by incorporating advanced technologies that reduce emissions and enhance energy efficiency. Thus, potential buyers should prioritize models that align with their sustainability goals.

Another trend affecting portable crusher demand is the rapid technological advancement in the industry. Features such as automation and smart technology are becoming essential in modern portable crushers. The ability to monitor equipment performance in real-time and integrate data analytics enhances operational efficiency and minimizes downtime. As such, buyers need to explore machines that offer these high-tech features, ensuring they invest in equipment that supports their long-term operational strategy.

Tips for potential buyers: First, assess your specific crushing needs and the materials you will be processing. This will help you choose a model that offers the best capacity and efficiency for your operations. Second, always consider the total cost of ownership, including maintenance and operational costs, rather than just the initial purchase price. Finally, keep an eye on market reviews and technological advancements, as staying updated will help you make informed decisions that align with future trends.

The impact of environmental regulations on portable crusher design is becoming increasingly significant as industries seek sustainable solutions. In recent years, stricter guidelines on emissions and noise levels have led manufacturers to innovate in ways that not only comply with these rules but also enhance performance. According to a recent industry report by Allied Market Research, the global portable crushing equipment market is projected to reach $2.9 billion by 2025, driven in part by the demand for eco-friendly technology that meets regulatory standards.

To successfully navigate the changing landscape of portable crusher design, it is essential for buyers to consider eco-efficient features. For instance, devices equipped with advanced filtration systems and quiet operation technology are not only compliant with current regulations but also contribute to reduced operational costs. Moreover, the integration of smart sensors for real-time monitoring can optimize fuel efficiency and minimize emissions, thus aligning with environmental mandates.

Tips: When evaluating portable crushers, prioritize models that offer adjustable settings to reduce noise and dust simultaneously. Additionally, inquire about the manufacturer's commitment to sustainability and their proactive measures to meet or exceed regulatory requirements. Always check for certifications that confirm compliance with national and international standards to ensure that your investment aligns with both legal obligations and market trends.

| Feature | Description | Impact of Environmental Regulations | Key Considerations |

|---|---|---|---|

| Energy Efficiency | Design focused on reducing fuel consumption. | Compliance with emissions standards is driving innovation. | Look for energy-efficient models to save costs over time. |

| Noise Reduction | Incorporation of quieter operation technologies. | Regulations on noise levels in urban environments are impacting design. | Consider models that meet local noise ordinances. |

| Mobile Connectivity | Integration of IoT for real-time monitoring. | Data collection can help ensure compliance with environmental regulations. | Evaluate connectivity features for remote monitoring. |

| Recyclability | Use of materials that are easier to recycle. | Regulations pushing for sustainable materials in construction equipment. | Research the recyclability of the unit components. |

| Compact Design | Smaller footprint for ease of transport. | Regulations may necessitate equipment size limits in certain areas. | Consider portability features for accessing remote sites. |

When considering the acquisition of a portable crusher in 2025, it is essential to conduct a thorough cost analysis to weigh investment against value. The initial purchase price can often be significant, influenced by factors such as size, capacity, and technology. However, understanding the long-term benefits is crucial. A higher upfront cost might translate to greater efficiency, durability, and lower operational costs over time, providing more substantial returns on investment (ROI).

In addition to direct expenses, potential buyers should consider maintenance costs, fuel efficiency, and the versatility of the machine. These factors can significantly impact the total cost of ownership and operational productivity. Furthermore, as technology advances, newer models may offer features that enhance performance and reduce labor costs, making them a worthwhile investment despite a higher initial price. Thoroughly evaluating these elements will help buyers make informed decisions that align with their operational needs and financial goals in the evolving market of portable crushers.